FAQs & Support

MAKING THE WORLD’S BEST OUTBOARD PROTECTION SINCE 2000

Fabric Colours & Polysoft®

Polysoft® and Polysoft® II & Available Colours

We have worked with our fabric suppliers to develop a fabric that is perfectly suited to the marine environment and will protect your valuable investment without causing any damage.

Please make sure read the care and maintenance instructions supplied with your covers to ensure you get the best possible results.

Currently Polysoft® P1 and Polysoft® P2 comes in the following colours:

Polysoft® Original

Polysoft® Original |

Polysoft® II (P2) |

| CARIBBEAN BLUE | BLACK |

| HARBOUR BLUE discontinued | CHARCOAL |

| AQUA GREEN discontinued | LIGHT GREY |

| BURGUNDY discontinued | NAVY BLUE |

| WHITE *see disclaimer | |

| RED |

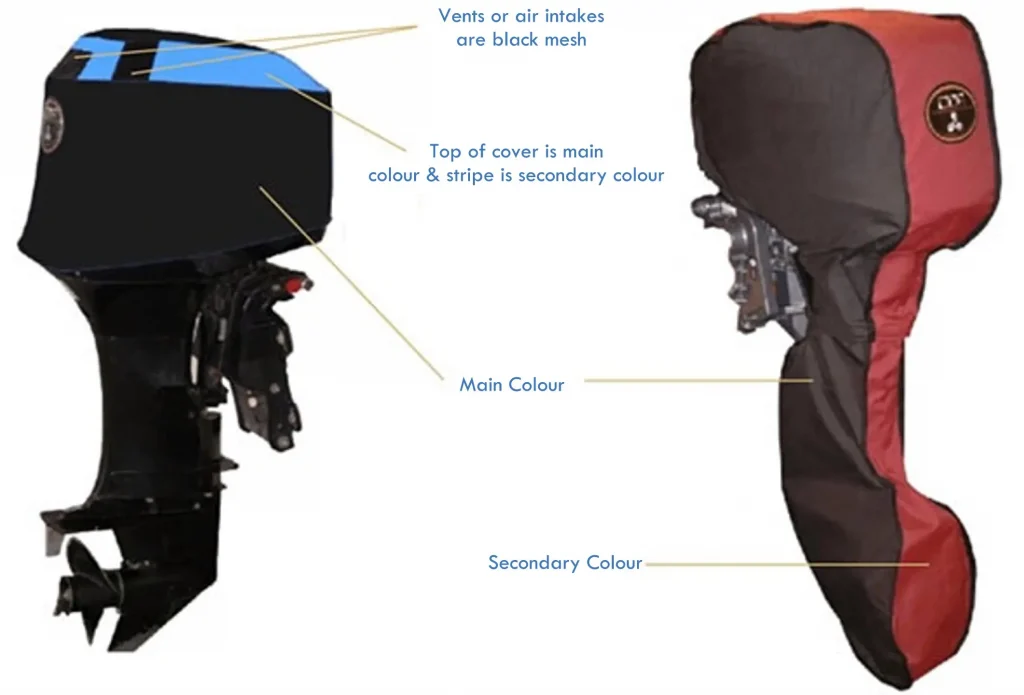

Covers can be made in one solid colour or in two contrasting tones. Specify on the order form your choice of Main and Secondary colour if you prefer the two tone option. Below are some 2 tone suggestions showing how they will look together.

Polysoft® offers a strength, dimensional stability, and abrasion resistance with the addition of a lightweight, non-woven soft fuzzy polyester backing. Polysoft also features great water, UV, and mildew resistance to endure marine environments.

What is Polysoft®?

In technical terms the material is an acrylic polymeric impregnated fabric. In other words it is a coated polyester that has a very high breaking strength, abrasion, mould and ultraviolet resistant. It also has excellent colour fastness and lasting outdoor durability. In fact Outboard Covers offers a 2 year guarantee against fading and rotting. We also offer a 12 month limited warranty on our high quality workmanship. We have sold covers all over the World and our reputation is second to none for service and quality.

Why not Vinyl?

People also ask what is wrong with using vinyl or a padded vinyl won’t that stop the noise more and offer more protection?

Yes it MAY but as it is not breathable it will cause moisture to build up under both the cowl and cover. This will corrode the motor and damage the paint and decals.

Most people are not aware that a replacement cowl is extremely expensive and if new decals are required these are usually extra and can cost as much as one of our Splash® covers.

This is typically what would happen if you made your outboard cover out of a material that does not have breathability such as vinyl or even neoprene which is used on wet suits. They do not have what Polysoft® has!

Just another reason to fit an OCA cover.

Our new, exclusively made fabric with higher specs, nicknamed P2 fabric.

Polysoft® II offers strength, dimensional stability, and abrasion resistance with the addition of a lightweight, non-woven soft felt backed polyester backing. Polysoft® II also features great water, UV, and mildew resistance to endure marine environments.

What is Polysoft® II?

In technical terms the material is an acrylic polymeric impregnated fabric. In other words it is a coated polyester that has a very high breaking strength, abrasion, mould and ultraviolet resistant. It also has excellent colour fastness and lasting outdoor durability. In fact Outboard Covers offers a 4 year guarantee against fading and rotting. We also offer a 3 year limited warranty on our high quality workmanship (commercial applications we offer 2 years on both). We have sold covers all over the World and our reputation is second to none for service and quality. Current colours this new fabric is available in are black, charcoal and light grey.

The black is a lot blacker than our previous fabric and other colours will be added to our range over the next 12 months.

Technical Specifications:

| Polysoft® Original Spec | Polysoft® II Spec |

| Med U.V. resistance | High U.V. resistance |

| 100% Woven polyester material | 100% Woven polyester material |

| UV resistant rated 3 out 5 on a UV scale Grade -3 @1000 hours | UV resistant rated 4 out 5 on a UV scale, Grade >4 @1000 hours |

| Spray Rating: 90 | Spray Rating: 100 |

| High tear and abrasion resistance | High tear and abrasion resistance |

| Excellent mould and mildew resistance | Excellent mould and mildew resistance |

| Med/ High water resistance | High water resistance |

Why not Vinyl?

People also ask what is wrong with using vinyl or a padded vinyl won’t that stop the noise more and offer more protection?

Yes it MAY but as it is not breathable it will cause moisture to build up under both the cowl and cover. This will corrode the motor and damage the paint and decals.

Most people are not aware that a replacement cowl is extremely expensive and if new decals are required these are usually extra and can cost as much as one of our Splash covers.

This is typically what would happen if you made your outboard cover out of a material that does not have breathability such as vinyl or even neoprene which is used on wet suits. They do not have what Polysoft® has!

Just another reason to fit an OCA cover.

We have developed a camouflaged fabric which we can make in a single colour (no secondary option). These do not have the same breathability as Polysoft so we recommend removal after use to prevent moisture build up.

PLEASE NOTE: these covers cannot be printed on BUT will carry the standard OCA logo

Below is an example of an OCA camouflage cover.

Below is an example of what colours go where on your cover/s. The main colour is considered to be the one that is most prominent and the secondary colour is the highlight or stripe.

Please note that all our covers are made to model specific patterns so the location of the secondary colour will vary according to each pattern.

*White Fabric Disclaimer

It is highly recommended that hands and the motor are clean before handling the white covers. Oil and grease will mark the fabric and may be hard to remove.

The white fabric Polysoft ®II is liable to show dirt more easily. Responsibility for the fabric or any part of the cover becoming dirty or marked with use cannot be accepted by the manufacturer.

White Fabric (P2) is slightly transparent and you may see the branding on the existing cowl come through the cover. The perfect alignment of the cover graphics and cowl graphics cannot be guaranteed.

As with all covers, the use of a washing machine is NOT recommended. Please follow the supplied care instructions carefully.

White fabric may also come with small dark colour dots which is unavoidable and is caused by dust particles in the air when the fabric is woven.

The exhaust port on the rear lower part of the motor (Verado motors) ‘will’ become marked with black exhaust deposits from this port, this is unavoidable.

FAQs & Info

Learn how to choose the right size for your outboard motor, including buying, delivery and costs.

- General FAQs

- Fabric Colours/Polysoft

- Cover Care

- Warranty

- Documents & Videos

- Terms & Conditions

- Pricing & Ordering

- Price Guarantee

- About Us

Distribution Information

Still Looking for an Answer?